Hello again, internet. I had a very pleasant and restful holiday season this year, traveling up to Connecticut to spend some fun times with my parents, my sister, and my girlfriend. It was very restorative to get out of the city and out of my usual routine for a little while. On New Years', I went full old person and went to bed around 10:30 after a very nice 65 mile ride up to Nyack. I poached some trails on the way, which started out as a nice gravel-ish climb but then deteriorated to some pretty sloppy single track. A little ambitious for my trusty road bike, but lots of fun anyway.

my beloved ciocc, soon to be upgraded from its period correct build to a 10sp campy group.

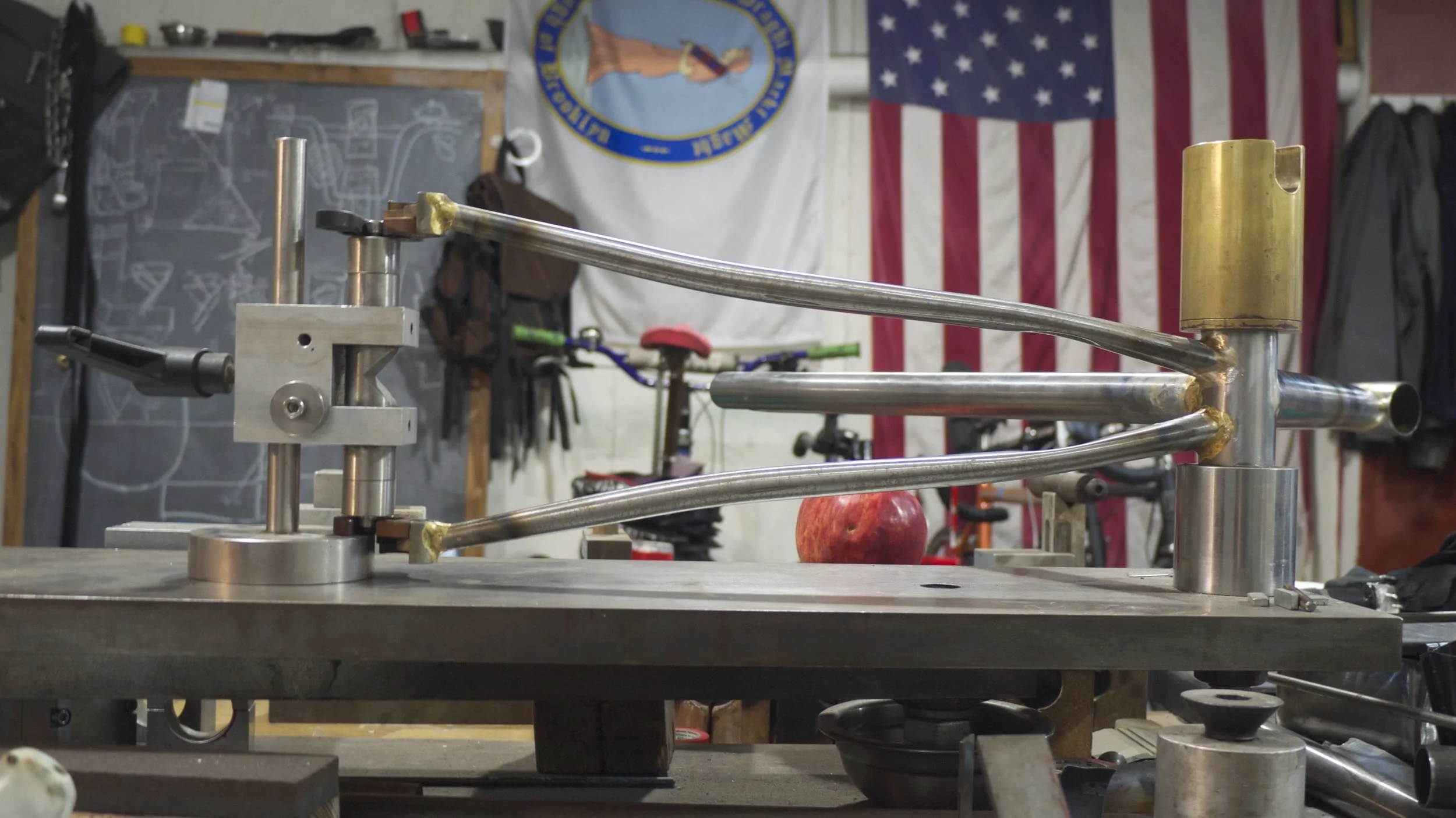

Although i did not spend any of my holiday time in the workshop, i did get quite a bit done since last I posted. Emily's bike has made lots of progress- the front triangle is complete and aligned, the chain stays and rear dropouts are attached and aligned, and the seat stays are mostly mitered. I think we are a day or two away from being a rideable frame! Here is the bike in its current state:

I borrowed a wheel from work to use as a test piece in the rear end of the bike- it has a 38mm tire and a 160 mm disc rotor mounted, so it fits all of the critical dimensions that i need to make sure will clear the frame once everything is built.

Before attaching the chain stains, i wanted to be sure that there would be enough tire and mud clearance, so i dimpled the stays. Dimpling is common practice among frame builders and designers, as it doesn't hurt anything, requires only a little bit of planning, and can save your bacon when it comes to clearance issues. I laid out the stay as it would be once installed to determine where the fattest part of the fattest tire would land. Once i found that, I marked it all up and set up the arbor press:

The arbor press is a simple tool that smushes things with a half-ton of pressure. I supported the chainstay in a wooden tubing block and then lined up the bit with my scribed marks. A little nerve-wracking for the moment that you feel the stay squish, but it came out awesome.

Here you can see the dimpled stay after brazing to the bottom bracket. It fell nicely where the fattest part of the fattest tire that this bike could accommodate would go. Success!

One of the challenges on this build was switching jigs partway through the build. I stared out on the Anvil jig, which is a wonderful tool that i was already familiar with from UBI and my earlier projects. However, our jig was on loan, and the owner took it back, so we were left with Lance's trusty Bringheli jig. The Bringheli is a very cool jig- it is hugely versatile and allows for a lot of different dimensions and standards without having to invest in additional small parts or tooling. However, it has no real indicators or labeling and thus takes quite a bit longer to set up than the Anvil did. Furthermore, given that this is my first build in this particular jig, I also spent a whole lot more time checking my work. Once I had the stays attached, I brought it right over to the alignment table to make sure that everything was straight and proper:

Everything came out great. Here you can see the bottom bracket shell clamped under the big brass block. The middle metal V of the contraption that is sitting in the dropouts in the picture starts out being pushed up against the centerline of the seat tube. That gives you the centerline of the front triangle (as long as your front triangle is straight). Once you have that centerline locked down, you bring it back to the dropouts and see where they land. Ideally, the center of the rear will be the same as the center of the front.

Once I got all that squared away, I started mitering the seat stays. Looking good! With some luck I will be back next week with the stays attached as well. Once the frame is all together, we move on to the fork!