Well, my projects keep on moving nicely forward over here in NYC. The other project i took on, besides the big raleigh road restoration, is a really exciting dirt road shredder/light touring monster for my friend Emily. Emily and I go way back, at this point. We both attended the mossy intellectual haven of Reed College in Portland, OR several lifetimes ago. Although we didn't know each other at that point in history, it is a small school and we bumped into each other. After graduation, we both ended up working for Bike Gallery in Portland for several years. I started my tenure at Bike Gallery as a salesperson, and, not being naturally inclined towards sales, was somewhat lazy and spent too much time browsing pictures of people's custom bikes on the internet while Emily actually worked. When she packed up and moved, first touring down the coast and then to NYC, I said that someday i'd build her a sweet steel frame. Now that we are in the same city at the same shop once more, the time has come.

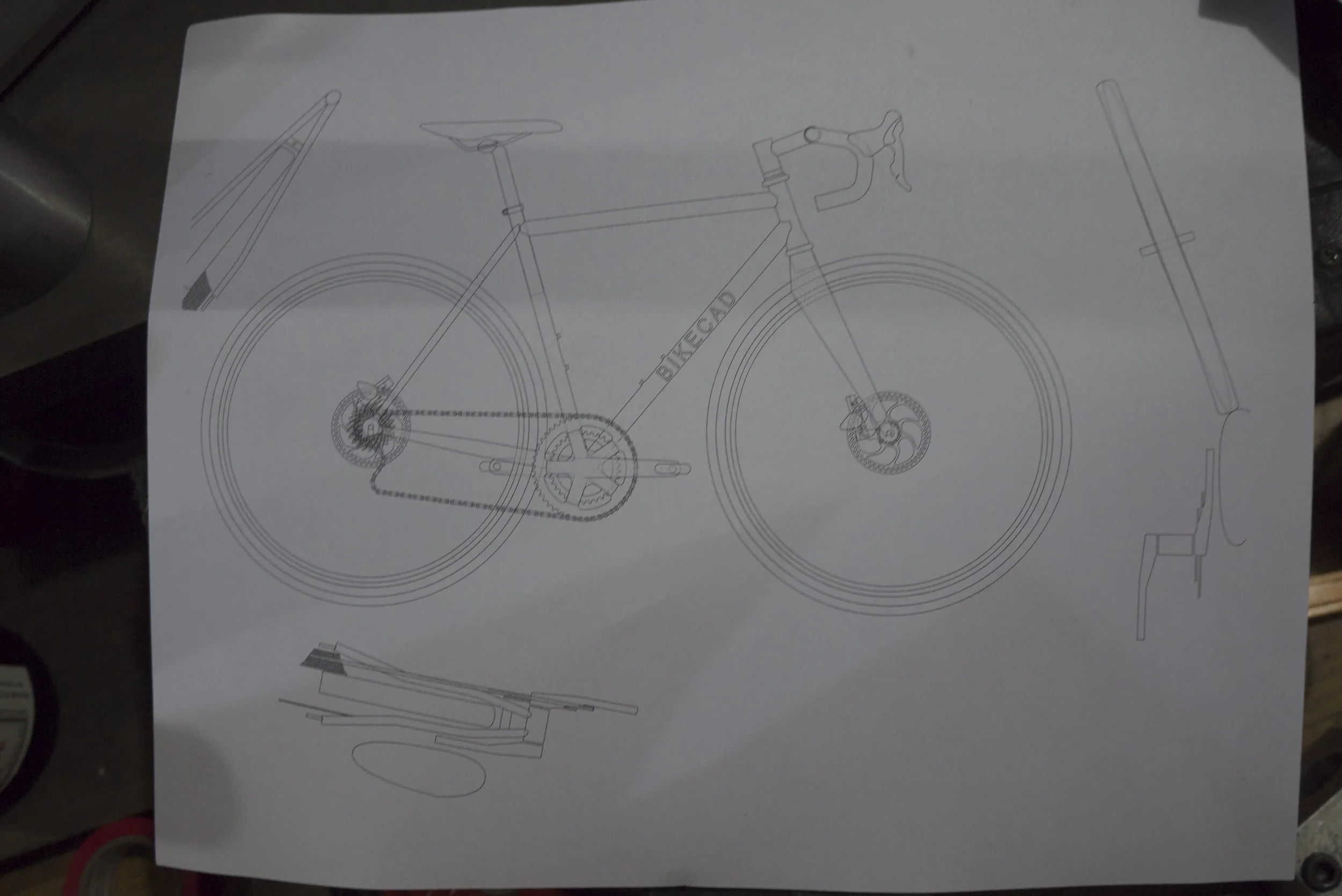

Initially, Emily came up with the bike as a touring bike. However, as we talked it over a couple of times, it evolved into a dirt road shredding machine with the capacity for a light to moderate rear load. I did my thing with sketches and BikeCad, and spent a lot of time mulling over tube sets, axle standards, and brake systems. In the end, I felt (and Emily agreed) that if we were going to build a modern bike, in a modern category, for a modern drivetrain, it should adhere to whatever standards are most appropriate. so, given that a bike like this has disc brakes these days (for a lot of good reasons), i felt it should also have thru axles. Most of Emily's riding on the bike will be unladen, so i want it to be a little lighter than the Rando-Gnar. Here is the result:

Mixed Columbus Zona double oversize 8/5/8 tubeset, tapered headtube for carbon fork compatibility, clearance for up to 43 mm tires or 40 w/fenders, 12mm front thru axle tapered unicorn fork, 142x12 rear thru axle, and disc brakes.

So, I ordered up tubing, printed off mitering templates and dove in!

It has felt very, very good to have a full size project to sink my teeth into again. As much as I enjoyed Boson's cargo bike project, it is very nice to have jigs and fixtures pre made for me. And while all of my filing and emery'ing muscles are perpetually sore from mitering and cleaning tubes, it is a good sore.

Once I got all the miters cut and things lined up in the jig, I tacked everything up. The tacks held everything in place so that I could check the alignment before tinning the joints. As I spoke of earlier, tinning is a way to build up internal fillets within your joints. Here is the front triangle tinned:

As you can see, the fillets are not fully formed on the outside at all, but there is already 36" of 3/32" brass filler rod holding the frame together before I have even completed a single joint. For a bike that I would like to punch above it's weight class as far as being able to carry bags for a couple days while also being pretty light and confidence inspiring on mixed surfaces, strong joints are a must.

Here it is all brazed up! I have a couple more photos up on the project page here. Lots more coming soon as I work through the rear triangle, and then a really cool fork!